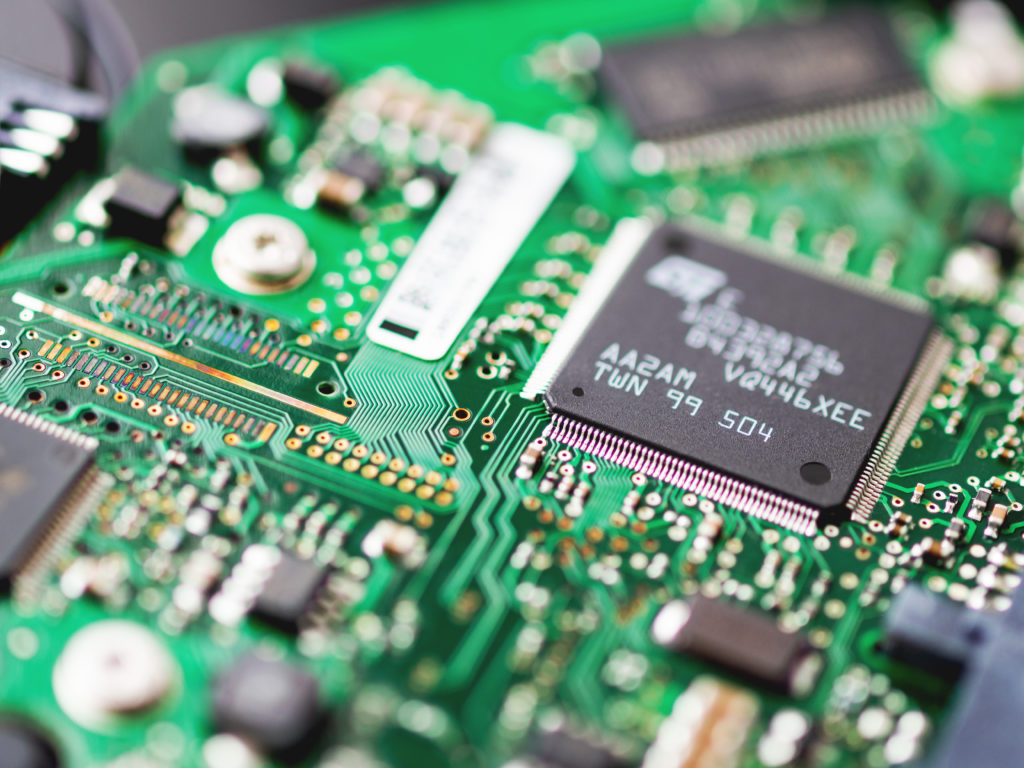

Recent generation medical devices are equipped with high-capacity processors and analog interfaces for a number of different sensors and actuators. According to the respective specification, electromechanical components make sure the device is operated fully or partially automated.

For the safe operation of the device, a hardware base designed as part of the system concept is vital. Depending on the classification of the medical device, it also detects faults identified in the risk analysis.

Our qualified engineers have gained a varied experience in all fields of actuating elements, sensor technology, electrical engineering as well as analog and digital circuit technology in designing innovative and safe hardware.